As high-brightness LEDs (HBLEDs) penetrate all avenues of the lighting market, various semiconductor manufacturers are offering constant-current drivers. Only by choosing a driver IC capable of meeting the flexibility and control required by today’s applications can the true potential of HBLEDs be unleashed. Theatrical lighting, for example, often requires high dimming resolution while dynamically adjusting the current to account for fluctuating power sources and operating temperature. Since the quality of light output is intrinsically tied to the capability of the LED driver, it is important to choose a system that has the right specifications.

Today’s HBLEDs typically have a nominal current rating of 300 to 700 mA. As the envelope of light output is pushed, devices requiring more than an ampere are appearing in the market. In all LEDs, due to the voltage-current relationship and the binning approach used by manufacturers, a constant-current source is used for accurate control of the light output. Choosing the right constant-current regulator depends on the operating voltage of load and source, the desired efficiency, and the cost and size of the system.

A high-power resistor in series with LEDs would be the simplest form of current regulator. However, since it alone cannot adapt to changing source voltages or the non-linear VI characteristics of an LED, a closed-loop system that changes the resistance based on output current may be used. In either case, the energy not used by the LED is dissipated as heat by the linear regulator, leading to an inefficient system. In most HBLED applications, switching regulators offer better efficiency over a wide range of operating voltages.

HBLED lighting fixtures designed to replace incandescent and fluorescent bulbs must provide better efficiency and quality of light while maintaining low cost. An integrated switching regulator used in lighting applications must require minimal external components and have good current regulation.

DIFFERENT TOPOLOGIES

While switching regulators can have diverse forms, they all operate using the same principle of moving small and controlled quantities of energy from the source to the load. The type of topology that is chosen depends on the type of conversion that is required. A boost topology is used when source voltage is lower than the required load voltage, while a buck allows the source voltage to be greater than the load voltage and is typically used for driving LEDs.

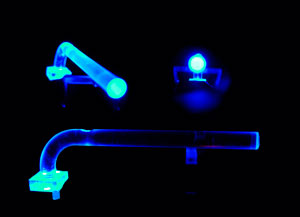

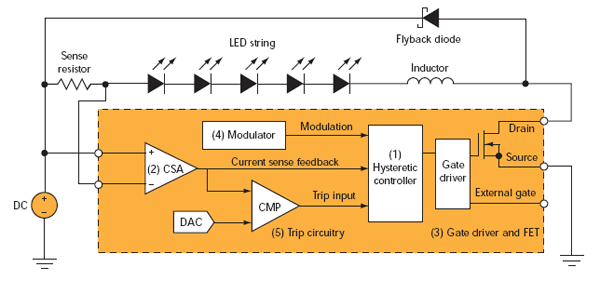

The main control system in any buck regulator is the hysteretic controller. This block regulates the current through the inductor by turning on a switch when it is below the lower threshold and vice versa. A shunt resistor is a convenient method of sensing the current, and by pairing it with a differential current sense amplifier (CSA), a smaller resistance can be used to minimize power losses. The analog circuitry of the controller uses the feedback from the CSA. These blocks can be arranged in various combinations. Different LED colors differentiate the topologies.

In all three topologies, current flows through the inductor when the corresponding switch (field-effect transistor, or FET) is turned on. When the current rises above a predetermined limit, the hysteretic controller on each topology turns off the FET. As the current in the inductor persists, it conducts through the flyback diode until it falls below the lower threshold and the FET is turned on again. A system capable of faster switching will require smaller inductors to store magnetic flux between alternate cycles.

The topology with the red LED is configured with a low-side sense resistor located on the source pin of an N-FET. An inherent problem with this implementation is that current through the inductor can only be sensed when the switch is on. Once the current reaches the peak threshold and the switch is turned off, the hysteretic controller must use a timing circuit to turn the switch back on.

If during the off cycle the falling current does not reach the lower threshold or overshoots it, the off-time must be adjusted until the loop is stable at the required current ripple. As this technique has true hysteresis on only one side of the loop, it won’t be able to quickly adjust to fast transients of source and load conditions.

A hysteretic control system that can sense both falling and rising edges requires the feedback loop to remain in the current path regardless of the state of the switch. The topology used by the blue LED shows the sense element in the path of the inductor current in the charging as well as discharging phase. To achieve this, a high-side switch or P-FET is used. Because the RDS (resistance offered by the FET to current) is higher in P-FETs than in N-FETs, there is a loss in efficiency. Additionally, the high-side driver and the P-FET itself are generally costlier than a low-side driver and N-FET rated for the same switching capability. Finally, in the topology used by the green LED, the FET and sense resistor swap positions. This permits the use of an N-FET to increase efficiencies while the location of the sensing element allows inductor current to be sensed throughout the operation of the hysteretic controller.

Working as a system, the LED driver channel depends on five elements to create a topology that is efficient and robust while meeting the demands of HBLED applications: the hysteretic controller, the current sense amplifier, the gate driver and FET, the modulator, and the trip circuitry. The same blocks may be used for other topologies such as boost, buck-boost, and single-ended primary inductor convertor (SEPIC). To Read (Part – II) Click Here.

Article is posted by Optics For Hire – Optical Design Consultants.